The automatic axle box unloading machine works in conjunction with wheelset transport equipment (AGV) to transport wheelsets from a fixed area to the unloading machine station, automatically unloading the axle boxes.

And then sorted and transferred the axle box to shipping containers for storage. After unloading, the wheelsets are transported to a designated area by transport equipment. Once the shipping tray is full, the transport equipment delivers the axle boxes to the designated storage location.

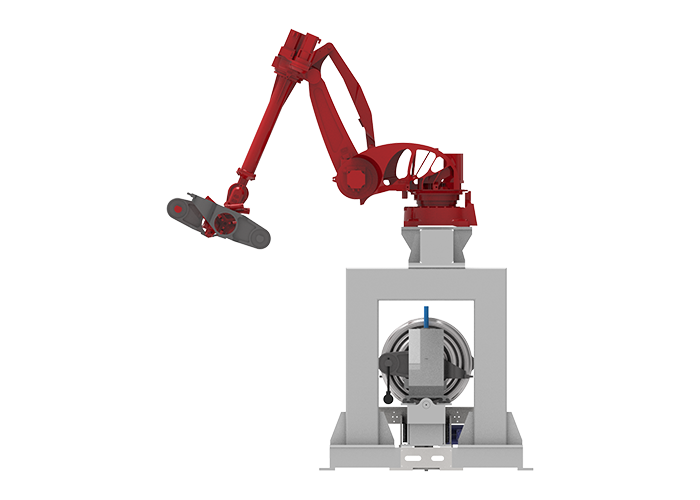

The robot is a gantry-type inverted robot capable of various movements and postures. Equipped with axle box grippers, it precisely grasps and transports axle boxes, operating at high speed and efficiency, significantly reducing labor costs,

and improving the company's image. It automates and intelligentizes production. The automatic axle box unloading machine can automatically receive work orders from the lean production management system, and the system can automatically start and report work during operation.